Distribution companies will be happy to know that in Acumatica 2020 R1, Warehouse Management System (WMS) includes wave and batch picking for rapid fulfillment. In this demo, a customer has placed an order for a custom laptop. The order is turned over to the warehouse side for fulfillment. The new features for picking and packing in Acumatica 2020 R1 make this more efficient than ever.

Video Transcription:

“Here I am out in the warehouse. Now, you’ll see I’ve already got a commerce order that has come in, but before I get to that, I’m going to talk about some new warehouse management enhancements that we’ve made in 2020 R1.

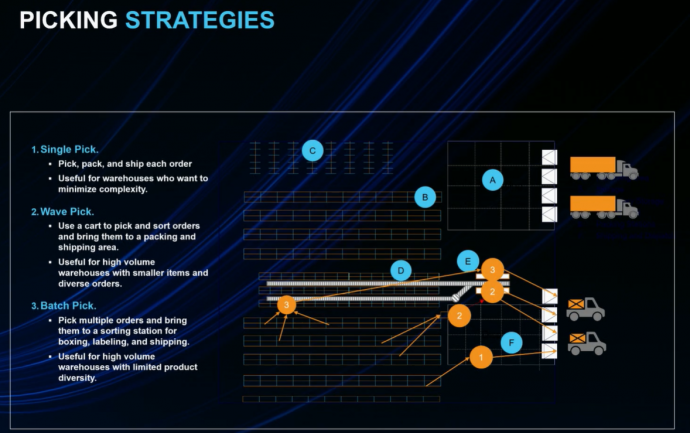

So here we have a pictorial of my warehouse. It’s a little bigger than the one I’ve got here on stage, but you get the idea. Prior to 2020 R1, we had option number one, just a direct pick. So if I had two or more orders waiting for packing, I do a direct pick by going out, grabbing order number one, doing my scanning, bringing it back to my packing and shipping station, shipping it up. Order number two, go back out to my warehouse, grab order number two, grab it, and bring it back to the picking packing station, pack it up. And it’s very healthy. I get a lot of exercise doing that, but maybe it’s not the most efficient method for a high volume warehouse.

So in 2020 R1, we’ve introduced wave and batch picking. For people that have a lot of orders that come in, that’s going to allow you to be much more efficient with the way you process. So we’re going to show batch picking. In batch picking, I’m going to go get a bunch of orders. I’m going to go out to my warehouse with one trip, put them on a cart, and then I’m going to bring them back to my packing station where somebody else can take over and efficiently pack them.

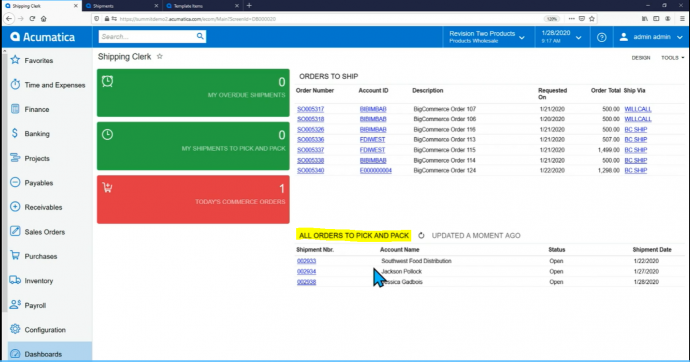

So after the preamble, let’s go back to my software and take a look at how it’s going to go. You can see my commerce orders that I have today. I take a look and I’m going to open up this one and I’ll go ahead and get this one through the process. So I’m going to start by creating a shipment. Now, normally I would have this set to run, to meet my shipping deadlines. An automated process would come and cause that to happen. Once that’s done, my dashboard is refreshed and you can see now I’m being notified of all the orders I have to pick and pack.

So one of the new things that we have to do is to create a print and pick lists. The options that I showed in my warehouse diagram are now available here, business as usual, wave, and batch. So we’re going to go ahead to our retail warehouse and pick the batch picking solution.

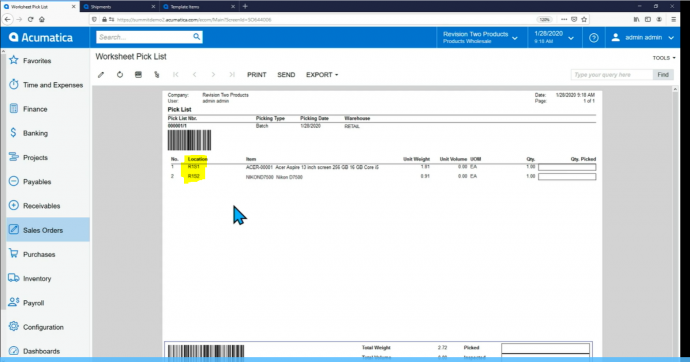

You’ll see, I can go in here and filter down the batch that I want to do. So if you want to filter by carrier, for example, or you want to filter by customer or pick out different things, you can set up the batch pick the way you want to do it. In this case, I’m just going to go ahead and manually pick two items to keep the scanning to a minimum. I’m going to process them. And now I’ve gone ahead and I’ve created my list. So the next step I have is to come to my picking worksheet and I’m going to go ahead and open that up and print my picklist. So you’ll see that this picklist, I went through it quickly.

I’ll have my new batch pick and I’ll have it in different locations, but it’s going to guide me through the warehouse so that I can go through here and then bring everything back to my sorting location.

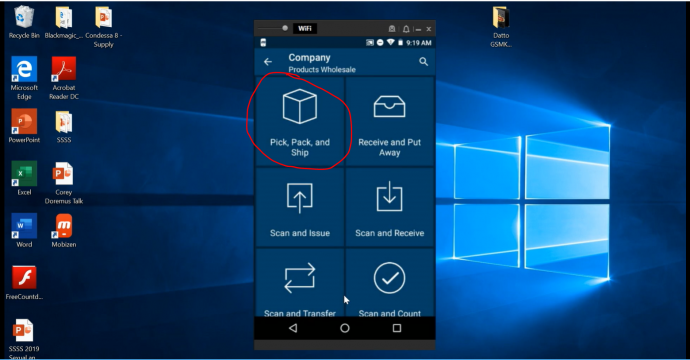

Let’s go ahead and switch to the mobile phone and I’ll take over as the warehouse guy. So here’s my Acumatica application. As I scroll down, get to the warehouse management area, I’m going to click warehouse management, and up in the top left is pick, pack, and ship.

I scan the picklist. It is appearing on my screen and that’s my batch pick. So now I’m aware that I’ve got to go to R1-S1. So I navigate out here to my area and I’m going to go ahead and scan R1-S1, and it says to pick an item. So I’m going to grab Jessica’s computer, go ahead and scan that. It immediately says we’ve got to do another location. So this one’s R1-S2. So I come here, scan that, and grab another item. This is why you take a cart out into the warehouse with you.

And we’re good to go with that now. So at this point, I’m ready to take things back to my packing station. It is looking a bit disorganized, but I’m still doing all right. The software’s working, maybe I’m just not. So here’s Jessica’s computer, ready to send in. So next I would go into pack mode.

So in the interest of time, I’m not going to show you going through and scanning this and putting each item into it’s a respective order. We’re going to have the Internet of Things that Ali is going to introduce is able to take this process, in terms of some future technology that we have, and make it even more efficient for the people in my shipping and packing and sorting stations to do their job.

For more tips visit https://www.calszone.com/tips

Learn more about Acumatica Cloud ERP

If you are evaluating a new ERP system, or are already using Acumatica, contact CAL Business Solutions. 860-485-0910 x4 or sales@calszone.com

By CAL Business Solutions, Acumatica and Microsoft Dynamics GP Partner, www.calszone.com

Follow us on Twitter: @CALERPNEWS