Every company that handles a physical product is, in fact, a wholesale distributor and needs the information and tools to effectively monitor and manage the distribution side of the business. All distributors, regardless of their specific product, rely on measurements to monitor business activities and performance, document successes and challenges, and help in decision-making. Sure, with mandatory accounting and reporting requirements are important, but smart management will incorporate those measurements into valuable intelligence that helps run the business more effectively and more efficiently.

Data is a good thing for all distributors, but when it comes to improving your business performance, having too much data can be a nightmare. You won’t be able to see clearly the most important factors of your business. Properly designed business measurements are valuable for any business and helps to improve decision making – things like profit and loss, cash flow, and inventory turns.

Beyond reporting, there are easy to see and digest tools available. We call them Key Performance Indicators (KPIs). Properly configured distribution KPIs can put you ahead of the competition, giving you a clearer picture of your business with less effort. Thousands of measurements have been defined over the year including many “common” measurements that virtually every distributor can use:

- Profit and Loss

- Profitability by Customer

- Cash Flow

- Inventory Turns

- On Time Shipping

- And more

What can KPIs do for my distribution business?

2 Types of KPIs: Historical and Predictive

KPIs can be used to see you overall distribution business status and performance, plus they can tell you where you’ve been and where you are headed.

Historical KPIs can be set up with alerts and warnings that monitor and detect exceptions, calling attention to issues or “push” alert messages sent via email or text.

Or, there are predictive KPIs, which can give you some insight into where your business is heading in the future months. By utilizing all your possible data, these KPIs can help you be smarter when it comes to ordering and planning. Sometimes these predictive KPIs use economic indicators, demographic trends, or even built-in specific industry indicators.

KPIs can also be set up to show you specific segments of your business, making it easier to pinpoint those problem areas of your business. You can set up KPIs to watch different areas of your business individually, or a KPI that is a combination across multiple segments. Having these visuals into inventory, on-time shipments, profitability, etc. for a single warehouse or the entire supply chain can make you successful.

Which KPIs should I be using?

When it comes to distribution businesses, it’s important to know, in real-time, which items are being ordered, how fast each item is being shipped, and the most profitable items. Without that insight, your business will struggle to survive. Here are some of the most used KPIs by distribution businesses everywhere.

- Profitability by item: Sales and Profitability by Item illustrates the raw power in a KPI. Having the ability to sort and summarize masses of data to give you business insights is key in making good decisions.

- Inventory turnover ratio: Easily spot low and high turnover items while keeping an eye on open POs and purchasing trends.

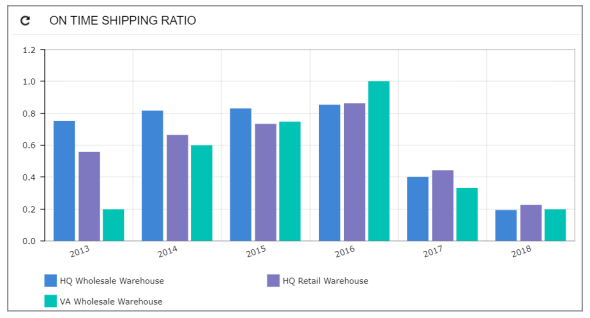

- On-time shipping ratio: This simple chart compares different warehouses on shipping metrics and trends. Analysts have a starting point to eliminate individual warehouse concerns and drill down into industry patterns.

Boost your business with KPIs and beat our your competition. Learn more about Acumatica, the cloud ERP, and which KPIs you need to track for your distribution business. Download the white paper now.

By CAL Business Solutions, Inc. Acumatica Partner